|

Selected

photos from:

Boeing

737-200

FAA Icing Certification of Hush Kit,

Aft Flap Modifications

This

program was for FAA icing certification of a Stage III hush kit installation

on a Boeing 737-200, and engineering development of an aft flap modification

to reduce drag and improve cruise fuel consumption. Alligator had responsibility

for all aspects of test equipment installation and data acquisition

for the program, involving 96+ channel pressure scanning, digital, analog,

low-speed and video data acquisition.

USAF KC-135 icing

tanker shot from cockpit of Boeing 737 test airplane

Instrumented Lear

Jet preparing to calibrate the icing plume

Ice build-up on 737

engine inlet (ice is dyed yellow)

Icing on engine pylon

and wing leading edge

Icing measurement

fence and lines marked on engine inlet prior to test

Flap angle visual

measurement jig allows fine adjustment of flap angles in flight

Flap angle jig and

airflow-visualization tufts

Aileron and aileron

trim tab angle visual measurement jig

Video camera and

lens de-fogger for videotaping ice formations during icing tests

Camera pod installed

on underside of wing

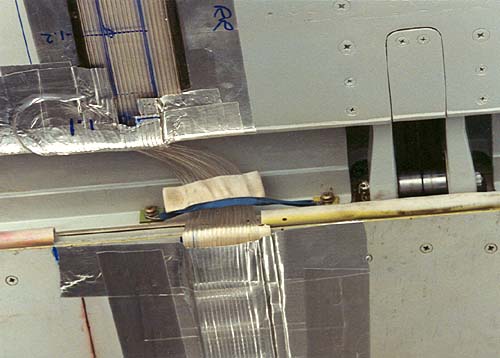

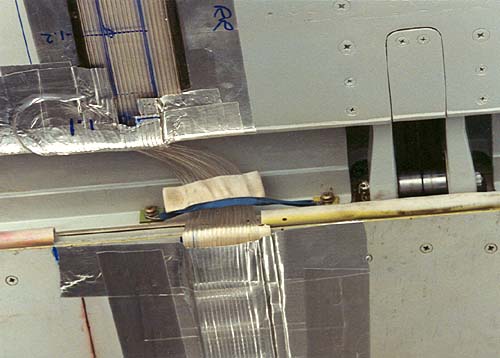

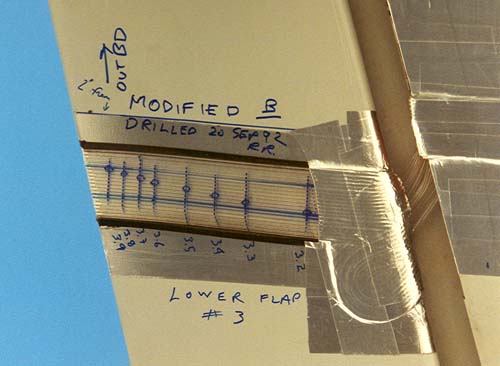

Strip-A-Tube installation

for measuring chord-wise pressure distributions

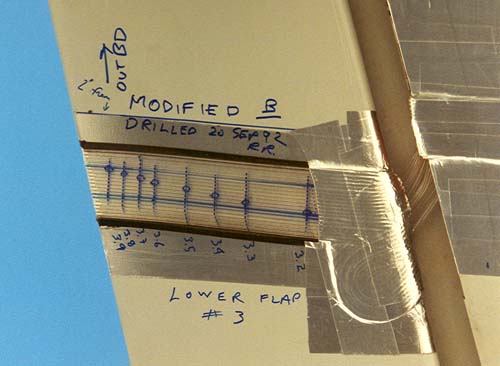

Port locations drilled

into Strip-A-Tube

Boeing's approach

to instrumented flight testing

Alligator's approach

to instrumented flight testing

Back

to Completed Projects

|